|

| This article was published in the January 2003 issue of the Rod and Line fishing magazine. |

Contrary to popular beliefs, the bait

casting reel in my opinion is more fragile than the spinning reel. No doubt the

one piece aluminum body does give one a sense of false confidence.

According to my experience, the

main trouble point of the casting reel is the level wind mechanism. The level

wind pawl to be more exact.

|

| Unscrew these tow thumbscrews to remove the right side plate. |

The level wind pawl is so thin

and delicate that should sand and grit be allowed to accumulate it will cause

hell in the slot. The main shaft of the reel can be damaged by a sharp fall

too. The gap between the spool edge and the reel body is so slight that any

bending of the shaft is enough to render the reel useless. Sometimes, the spool

and body can be corroded by saltwater if one is not too meticulous in cleaning

them after every trip out to sea or brackish water.

|

| Slowly remove the spool, and make sure you do not lose the brake blocks. |

Salt water can easily get inside

the reel and damage the bearings. The pinion gear, due to neglect and misuse

can get worn and will not drive the spool properly. Sometimes, the reel does

not engage, as the parts are not lubricated. As the reel can give a lot of

casting problem if the centrifugal brakes are damaged, they need to be in

pristine condition all the time.

|

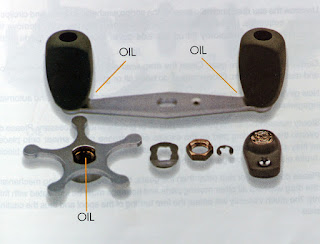

| The level wind mechanism and all the parts. Use light oil on these. |

The distance achieved in casting

depends a lot on the spool shaft bearings. They must be kept well-oiled and in

very good condition. Therefore I would like to discuss here some maintenance

tips with our readers. Of course there are many great sifus out there who know

a lot more, who I beg to share their knowledge with us here in the future.

|

| Do oil this spring and the thumb-bar mechanism. |

THINGS TO HAVE

A. The

small spanner cum screwdriver supplied together with the reel.

B. A

good Phillips and flat screwdriver that fit the screws of the reel to be

dismantle.

C. A

tray to keep all your parts. A discarded egg tray or those plastic trays for

mixing watercolor can be used too.

D. Tissue

paper to clean and dry the reel parts. They are very absorbent and cheap.

E. A

small stiff painting brush to clean the parts.

F. Thin

machine oil. (Mixed 1 part molybdenum disulfide oil with 2 parts sewing machine

oil.) Alternatively use Rocket Fuel oil.

G. Some

molybdenum disulfide grease.

H. A

pair of sharp tweezers to pick up fine parts and to remove springs and cir-clips

(e-clips).

I.

The schematic diagram of the reel.

| |

| The handle taken out. Oil the handle knobs and the star drag knob screw threads. |

DISASSEMBLING THE REEL

1.

Unscrew

the two thumbscrews to remove the right side plate.

2.

Gingerly pull out the spool. Do be careful so as

not to bend the centrifugal brake pins. In some reels, the brakes can slip out.

Do keep them in proper storage.

3.

Unscrew the level wind pawl cap and remove the

pawl.

4.

Remove the spring clip holding the level wind

worm gear bar and slowly pull it out. Be careful with the bearings so as not to

lose them. Wipe them clean with tissue and put one drop of thin oil in each.

5.

Clean the worm gear bar and worm gear with

solvent (petrol), dry and oil.

6.

Clean the reel frame, oil and grease all moving

parts. Pay special attention to the thumb-bar.

7.

Reassemble the level wind mechanism into the

reel frame.

8.

The mechanical brake cap must be removed so as

to take out the retaining clip holding the spool shaft. The spool shaft can

then be pulled out. Clean and oil. Use only thin oil as the free turning of the

shaft contributes to the casting distance.

9.

If the brass plate in the mechanical brake cap

is worn, flip it over and add a drop of oil to it.

10.

Clean the spool and oil (thin oil only) the

bearings on both sides of the spool.

11.

Turning back to the right plate, removes the

handle. Clean and oil.

12.

Unscrew the star drag knob. Do keep all the

spring washers, spacers and cir-clips in their proper sequence. (Refer to the

schematic diagram if you are lost). Remove the two retaining screws and slowly

lift up the side cover to expose the inside of the mechanism.

13.

Gently lift the drive gear. Clean the drag

washers (careful with the sequence) dry and reassemble them. (Some makes do

need oil or grease on their washers).

14.

Now gingerly clean the center pinion gear, spool

freeing mechanism and automatic re-engagement levers. Dry before applying oil

and grease.

15.

Slowly reassembly all parts, applying oil or

grease where necessary. Please do not overdo the lubricating parts the excess

oil or grease might smear onto places where they are not supposed to be. Try

your best to keep the centrifugal brake blocks and brake plates free from

grease or oil.

16.

Please do remember that other than the gears,

the spool disengaging mechanism and the drag washers and all other moving parts

and bearings must be lubricated with thin oil only. Too much viscosity will

defeat the free turning of the spool and thus the casting distance.

|

| Clean all the drag washers and gears. This particular reel does not need oil or grease on its drag washers. Some makes require the drag washers to be oiled and greased. |

THINGS TO REMEMBER

a.

Most of the things to remember are the same as

in spinning reel maintenance which I have covered in the November 2002 issue of

Rod & Line.

b.

For bait-casting reel, I would add that the reel

must be oil before every trip so as to keep it in tip top casting condition.

c.

Do oil the spool bearings, mechanical brake cap,

handle knobs and most important, the level wind. Make sure it is free from sand

and grit all the time.

d.

Remember to use thin oil (Rocket Fuel oil or

molybdenum disulphide and machine oil mixture). On the spool bearings and

shaft, as the free turning of the spool is the main reason for achieving the

distance casting.

|

| Unscrew these two screws to access the inside mechanism of the reel. Lift up the entire spool freeing mechanism, clean, dry, oil and reassemble. |

e.

Cover any springs or cir-clips with a finger

before trying to pry it out or else you whole family will suddenly get the urge

to go shopping every time you decide to clean your reel. (They will get a phobia

crawling on all fours helping you to look for missing parts).

f.

Do use a bent paper clip to help you remove

bearings from the reel body. When putting them back all you got to do is to the

bearing over the hole and press firmly with your thumb.

g.

Check every bearing by putting a pencil through

it before spinning. It should spin effortlessly. Should there be any problem,

it should be cleaned and oiled. If the problem persists, the bearing should be

replaced.

h.

Please bear in mind that this is a total

cleaning and oiling job, which I do at least once a year. Other time, do

remember to oil the handle knobs, the spool bearings and to clean and oil the level

wind pawl before every fishing trip.

|

| These parts free the spool for casting and reengage it to recover lines. Oil all moving parts where there is metal to metal contact. Grease the pinion gear. |

No comments:

Post a Comment